|

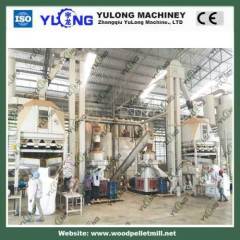

Zhangqiu Yulong Machine Ltd

|

wood pellet machine in China professional manufacture

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Efficiency high overload capacity, low noise, small vibration, reliable structure ,beautiful appearence

Specifications

wood pellet machine in China

1. professional manufacture in China

2. high efficiency low consumption

3. long working time

wood pellet machine can produce 2-8mm pellets, last pellet length can be adjusted optionally. The wood pellet machine is mainly applicable to crude fiber granulation ,such as: sawdust, rice husk ,cotton stalk, cotton seed hull, weeds and all kinds of crop straw, home wastage, waste plastics and the factory waste, the material of low adhesion rate, difficult to forming.

This type of pellet mill is widely used in the biomass-energy fuels plant, power plant, wood processing plant etc. It is the ideal pressing shaping equipments with low investment and high profit

characteristics:

1. vertical feeding

2. roller rotate,Centrifugal force role ,material distribute uniformly

3. two layer roler,saving cost ,good effect.

4. ring die,vertical structure, help pellet room temperature reducing

5. seperate discharging structure, improve the pellet forming rate

6. with good lubricate device, protect the machine bearing

7. feeding device with frequency conversion

Machine model: | XGJ series ring die pellet machine | ||

Use: sawdust,straw,stalk,rice husk,palm,other waste to press wood pellet, biomass fuels pellet, bioenergy fuels pellet | For:bioenergy fuels plant, power plant, wood processing plant, organic fertilizer plant, chemical plant etc | ||

Formation rate | 98% | ||

Die | Double layer | ||

Output | High | ||

Investment | Low | ||

Machine Run | Stable | ||

Auto Lubricate system | yes | ||

Operation | easy | ||

CE | Approved | ||

Quality | Guarantee | ||

Model | Power | Diameter of pellet | Ouput(Kg per hour) |

XGJ550 | 75+3+0.37+0.25+1.5 | Φ6-10 | 800-1000 |

XGJ560 | 90+3+0.25+1.5 | Φ6-10 | 1000-1500 |

XGJ580 | 160+3+0.25+2.2 | Φ6-12 | 1500-2000 |

XGJ850 | 220+4+0.55+3 | Φ6-12 | 2000-3000 |

XGJ880 | 315+5.5+3+0.55+3 | Φ6-12 | 3000-4000 |

Tips for making good pellets:

1. Changes in Raw materials pellet mill Rate with variable frequency

As we know,if you put the raw materials with continuous into the pellet mill,the pellet mill can work fluently,avoid the machine stop suddenly for accumulation raw materials on the hopper,so adjustments on feed rate and maintaining a consistent feed rate can be the key difference to how well the pellet mill operates,Even if the raw materials is perfectly prepared.

2. Changes in raw material characteristic by steam

Raw materials are hard like Oak,beech,rice husk which had lower binding power.it is not easy to press pellets and hold together,There is a pipe connecting the steam on the modulator,steam go through the modulator,the raw materials become soft, not only reduce the friction between roller and die,but also can increase capacity. Generally for wood pellet manufacturing steam is used.

3. Correctly setting up the distance between roller and die

The distance between roller and die is very important for the pellets making,the roller and die are wearing consumable parts,due to the abrasive nature and pressure of compression,the distance between roller and die adjustment can impact on how much energy the pellet mill uses,the quality of the pellets,Correctly setting up the distance between roller and die can increase the lifetime of roller and die.

www.yulongjixie.org