|

Zhangqiu Yulong Machine Ltd

|

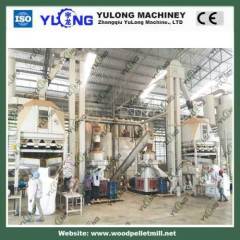

High Economical Complete wood pellet making production line

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Efficiency high overload capacity, low noise, small vibration, reliable structure ,beautiful appearence

Biomass energy complete plant applies to producing pellet of renewable resources, such as all kinds of wood, crops straw and sawdust. It mainly includes: conveying and chipping, drying, crushing, pellet, cooling and product packing.

Capacity 0.5-20t/h.

Application:

By pressing biomass waste, such as wood, straw, agricultural stalk, farm waste,rice husk, peanut shell, bamboo, empty fruit branch, pulverized coal, bagasse, alfalfa, grass,fibrous waste,waste paper etc. to be 6~13mm diameter pellets, The final pellets are Biomass energy fuel, the length can be adjusted.

Technical Parameters of wood pellet making production line:

Model | Power(kw) | Capacityt/h) | Product spec(mm) | Weight(t) | Dimension(mm) |

XGJ560 | 90+3+0.25+1.5 | 1-1.5 | Φ4-12 | 5.3 | 2600x1300x2300 |

XGJ720 | 160+3+0.25+2.2 | 1.5-2 | Φ4-12 | 9.5 | 2900x1300x2400 |

XGJ850 | 220+4+0.55+3 | 2-3 | Φ4-12 | 14. 2 | 3300x1400x3100 |

XGJ920 | 315+5.5+3+0.55+3 | 3-4 | Φ4-12 | 18 | 3800x1680x3400 |

XGJ1050 | 360 | 5-6 | Φ4-12 | 2 4.5 | 3800x1880x3500 |

Remark: that's 2tons/h pellet complete turn key eucalyptus pellet making line.

Requirement for raw materials:

Size:1-5mm(All the raw materials must be crushed into sawdust before going to wood pellet machine.If too long/ large, you may need a wood chipper, wood crusher.)

Moisture: Generally, 8-15% is best for producing good quality wood pellet. If too high, or too low, you need to dry or moisture them first.

Competitive Advantage:

It can change waste raw material, like sawdust, rice husk into biomass pellet, improving their utilization rate, energy saving and protect the environment.

Specification of wood pellet making production line

This item of Capacity 2 tons/H pellet production line includes wood crusher, dryer, conveyor, pellet mill, hoisting machine, cooling and separator, dust collector, packing machine and Electric cabinet. According you actual needs, you may control the production line by adjust the Electric

cabinet parameter.

Machines will be used in wood pellet making production line:

(1) Wood crusher and wood chipper(crush the big wood into small pieces like sawdust)

(2) Dryer (dry the raw material to proper moisture before making pellets, two type for choosing according to depends situation)

(3) pellet mill (press raw material into pellets)

(4)Cooler (cool down pellets and remove some moisture)

(5) drum screen/vibrating sieve (remove dust, and broken pellets)

(6)Packing machine (pack pellets into bags of required weight)

Notice:The above is standard pellet making line process; some processes are alternative and adjustable according to different raw materials and requirements of clients.

(7)wood pellets in bags, you can sell them in market directly.

Working Principle of wood pellet making production line:

Biomass pellet machine is one of the biomass molding equipment. It can make powdered biomass materials into pellets. Raw materials for the production of pellets are pressed by the pressing roller in the matrix. Due to the pressure and friction in the matrix, the materials are heated to a high temperature(nearly 60~80℃). As a result of pressure and temperature increasing, the materials were compressed into pellets. The output pellets will have very high strength after cooling.

Main biomass and pellet machinery we supply:

Biomass wood pellet machine line, feed pellet production line,wood pellet mill(ring/flat die pellet mill),animal feed pellet mill,feed mixer,grinding equipment(straw hammer mill, multifunctional hammer mill,wood crusher), crushing equipment(drum wood chipper, disc wood chipping machine,twin-shaft shredder,wood powder machine, sawdust machine), drying equipment(air flow dryer, rotary dryer), cooling and screening equipment, conveyor&elevator etc. All the products have got the ISO9001:9003 Certificate and CE Certificate with excellent quality and safety device.Also have passed the strict technical test by the related government offices and got good reputation among customers.

www.yulongjixie.org