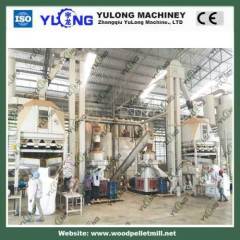

wood pellet making product line

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Efficiency high overload capacity, low noise, small vibration, reliable structure ,beautiful appearence

Raw materials of wood pellet making product line The material can be hard wood, rice husk, sunflower husk, peanut shell, branch, trunk, bark and other wood waste; A variety of crop stalk; Rubber; Cement, ash and other chemical materials.

Application range of wood pellet making product line Widely used in animal husbandry and aquaculture, and medium farms, feed mills, and brewing, sugar, paper making, medicine, cigarette factory in sectors such as organic waste to granulation. This product is suitable for medium and small farms, feed mills, organic fertilizer factory, chemical industry, etc., small investment, quick effect, risk free is the most ideal grain processing equipment.

Flowchart for wood pellet machine

Raw Material→Chippering→Crushing→Drying→Mixing→Conveying→Pelletizing→Cooling

1 Crushing Process:

When the thickness of raw wood material is >10mm, and >50 * 50mm(L * W), we need use the Wood Chipper to chip them into small pieces, then crush the small pieces into wood powder with diameter less 3mm by Hammer Mill (Crusher).

2 Drying Process:

The best moisture content to pelletizing is about 13-15%. Our Rotary Dryer is made up of Stove and Main Rotary Dryer, which can realize to reduce the moisture from 60% to 10%. Our stove is fueled by coal, which can save electricity consumption largely.

Typically, wood pellet line consists of

1. Raw Material Hopper(s)

2. Hammer Mill

3. Transfer Auger

4. Control Hopper

5. Pelleting Mill

6. Vibratory Dust Extraction System

7. Inclined Conveyor

8. Bagging Line

9. Control Panel

Model | Power(kw) | Capacityt/h) | Product spec(mm) | Weight(t) | Dimension(mm) |

XGJ560 | 90+3+0.25+1.5 | 1-1.5 | Φ4-12 | 5.3 | 2600x1300x2300 |

XGJ720 | 160+3+0.25+2.2 | 1.5-2 | Φ4-12 | 9.5 | 2900x1300x2400 |

XGJ850 | 220+4+0.55+3 | 2-3 | Φ4-12 | 14. 2 | 3300x1400x3100 |

XGJ920 | 315+5.5+3+0.55+3 | 3-4 | Φ4-12 | 18 | 3800x1680x3400 |

XGJ1050 | 360 | 5-6 | Φ4-12 | 2 4.5 | 3800x1880x3500 |

www.woodpelletmill.net

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Zhangqiu Yulong Machine Ltd [China (Mainland)]

Business Type:Manufacturer

City: Jinan

Province/State: Shandong

Country/Region: China (Mainland)